tools and some of the materials

tools and some of the materials

End Result

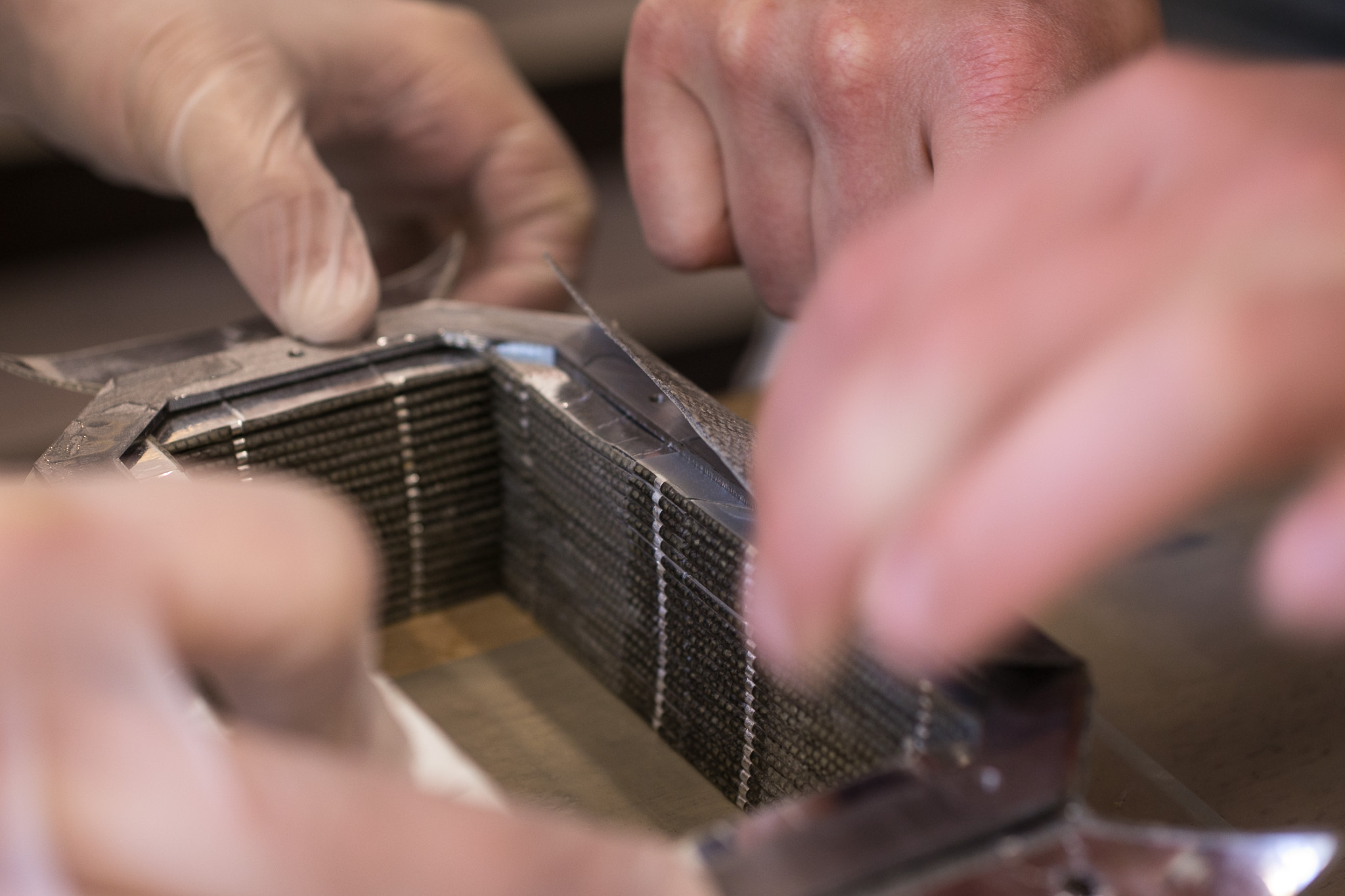

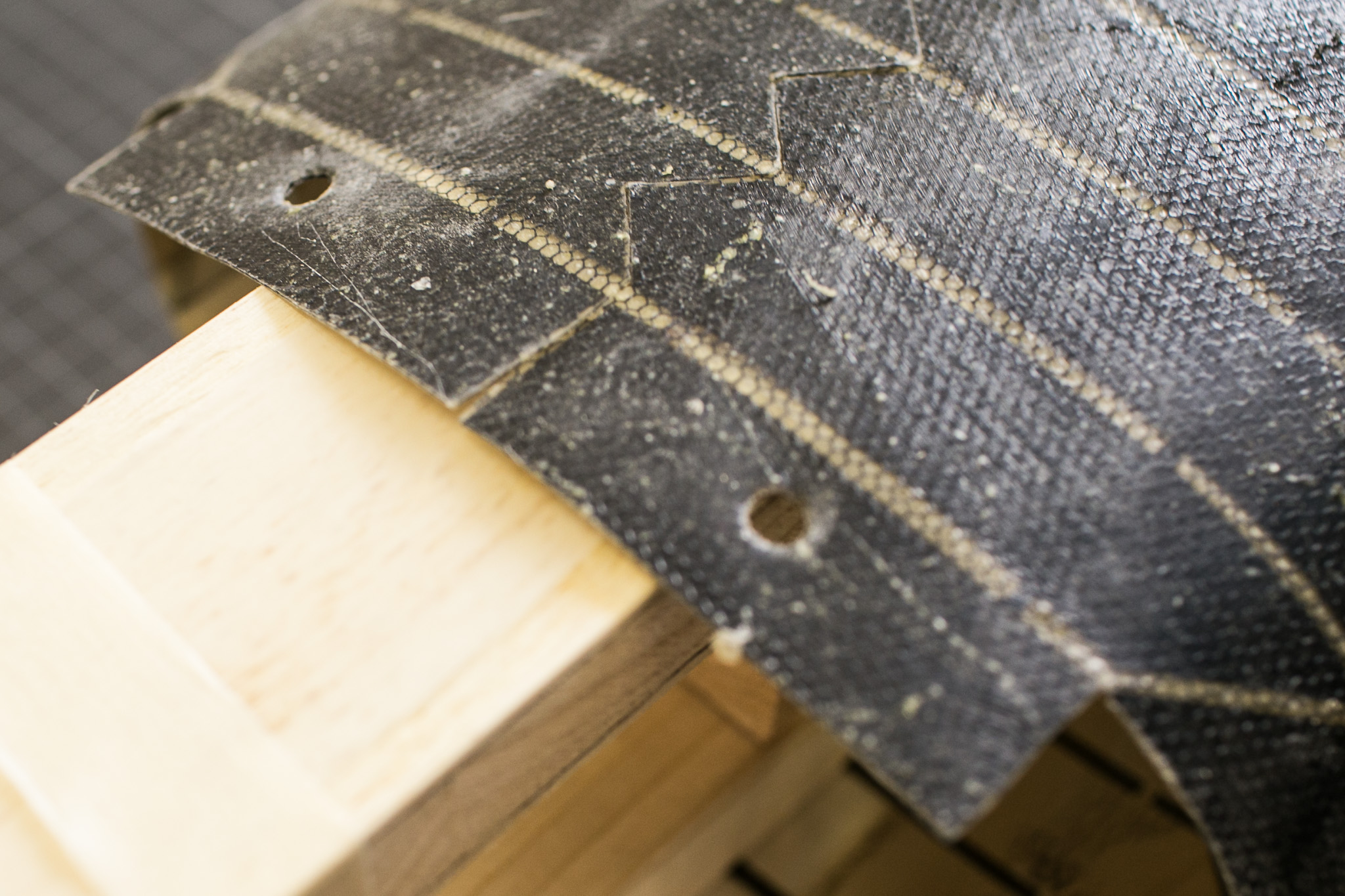

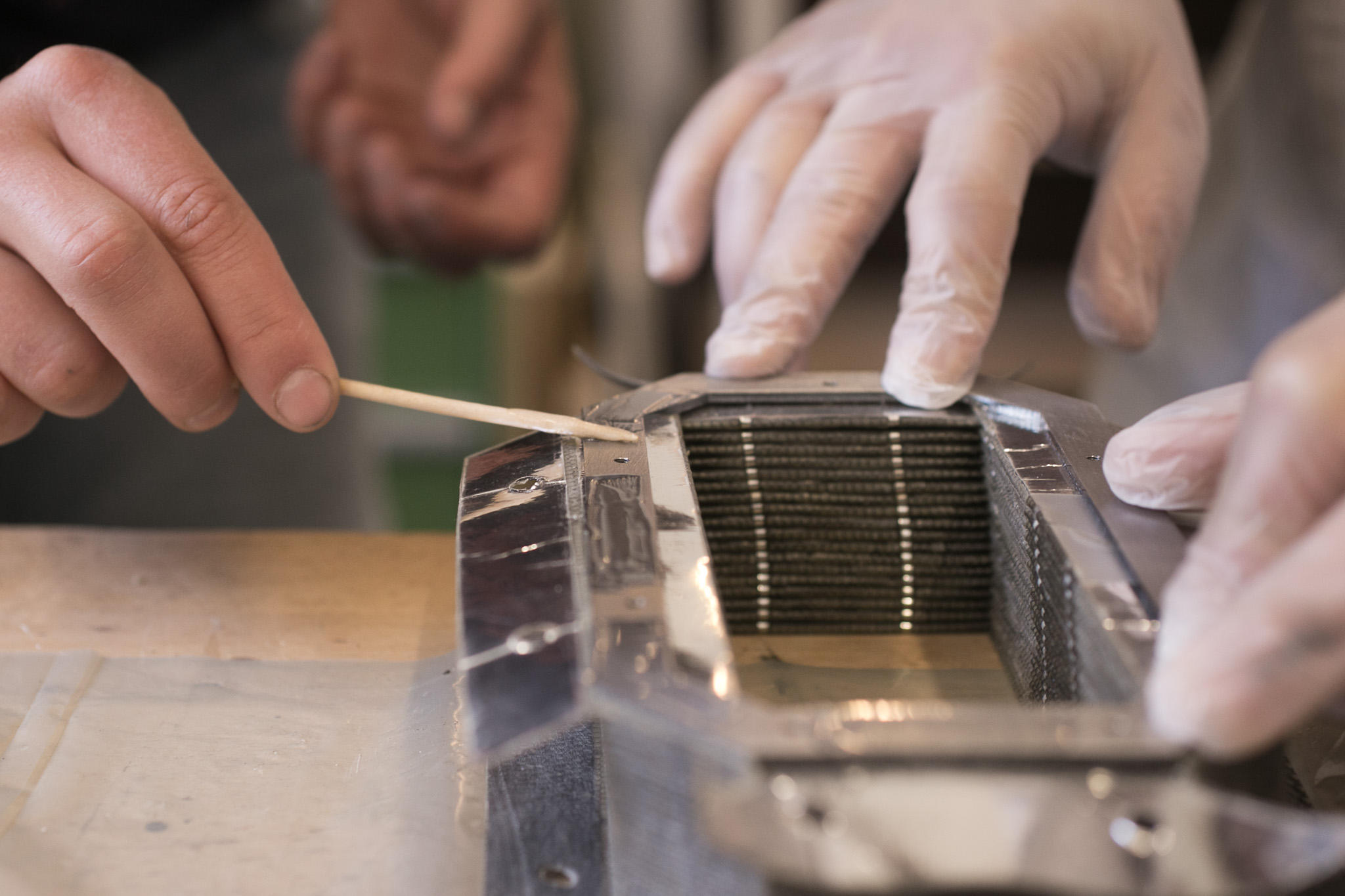

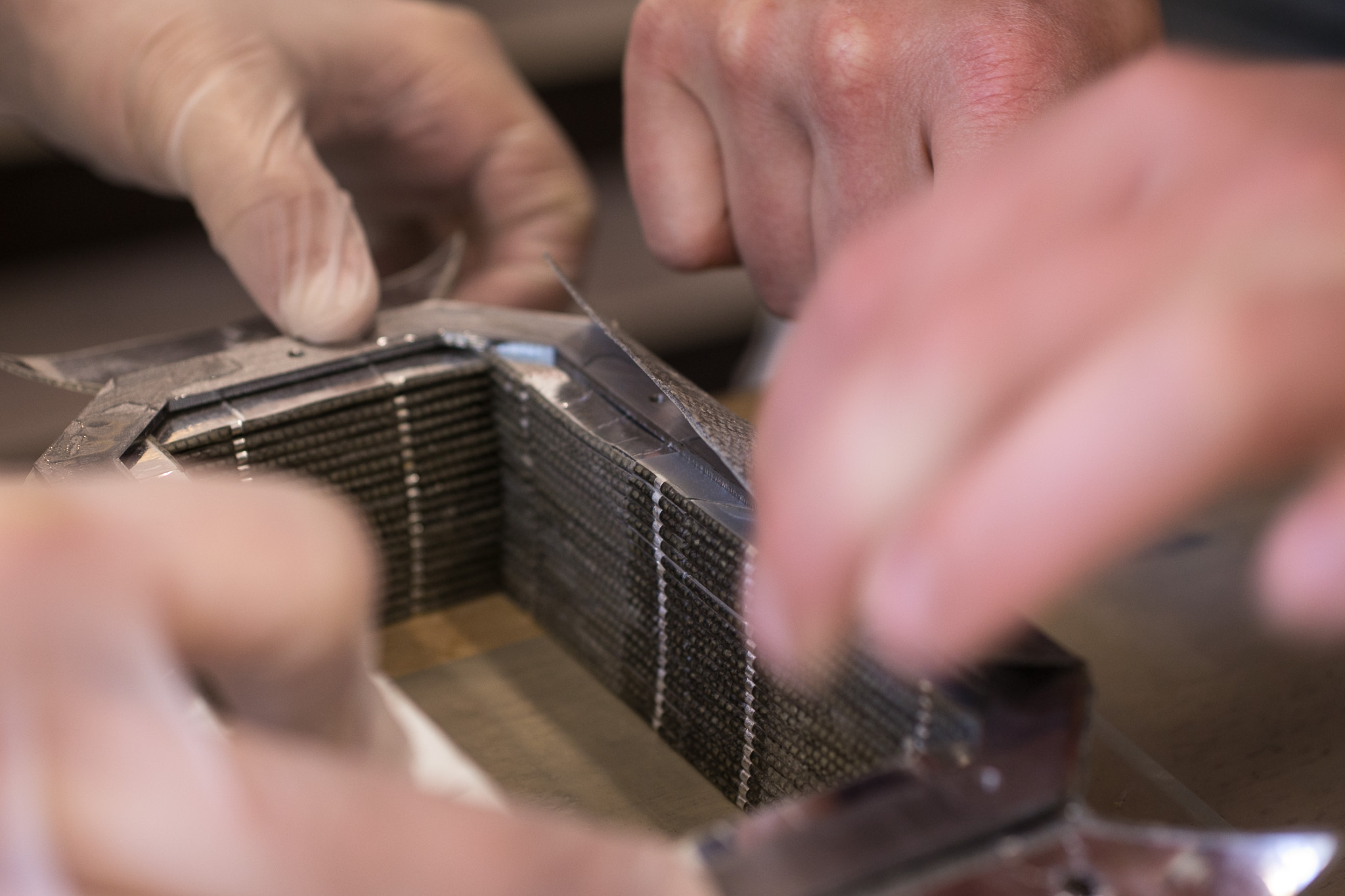

folded bellow with metal frames

folded bellow with metal frames

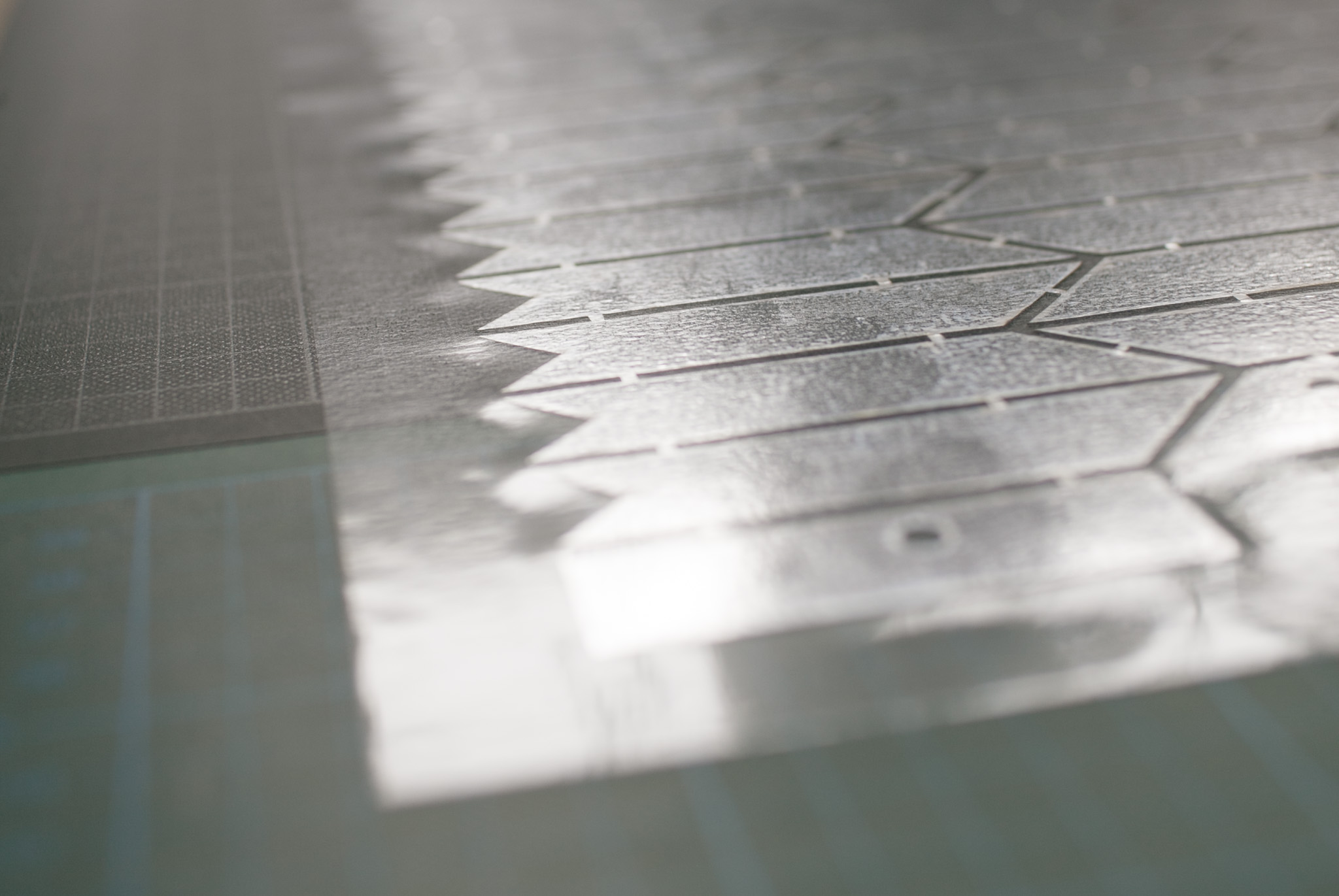

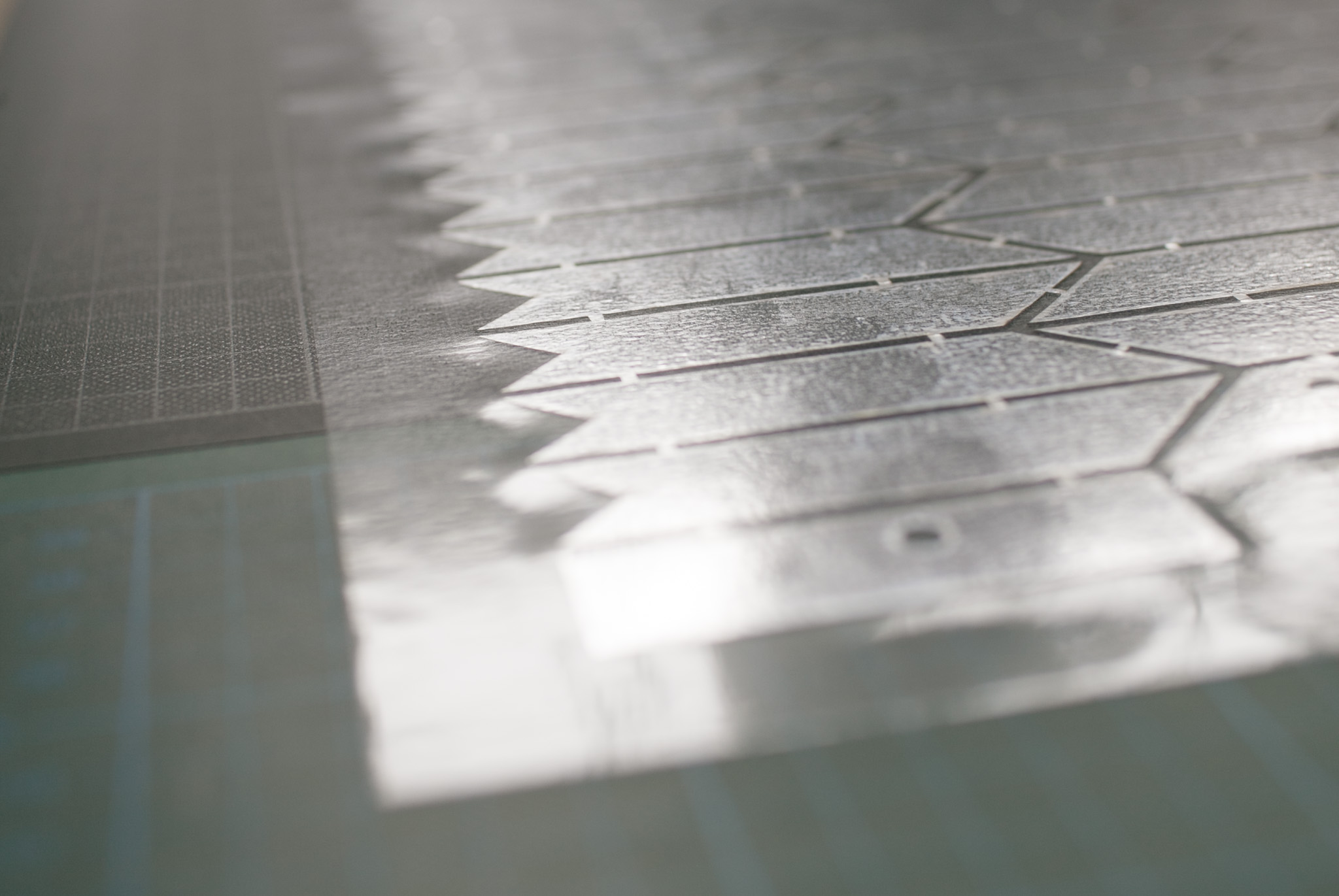

Before laser-cutting, glue the mirror film to the cardboard.

Load the provided file to your laser-cutter and try cut settings with a test piece of the material. Then, cut the sheet. As material we used woodfree cardboard from Igepa (Art.-No. 354-97).

Further we got the metal frames professionally produced. All its holes need a M3 female screw threading.

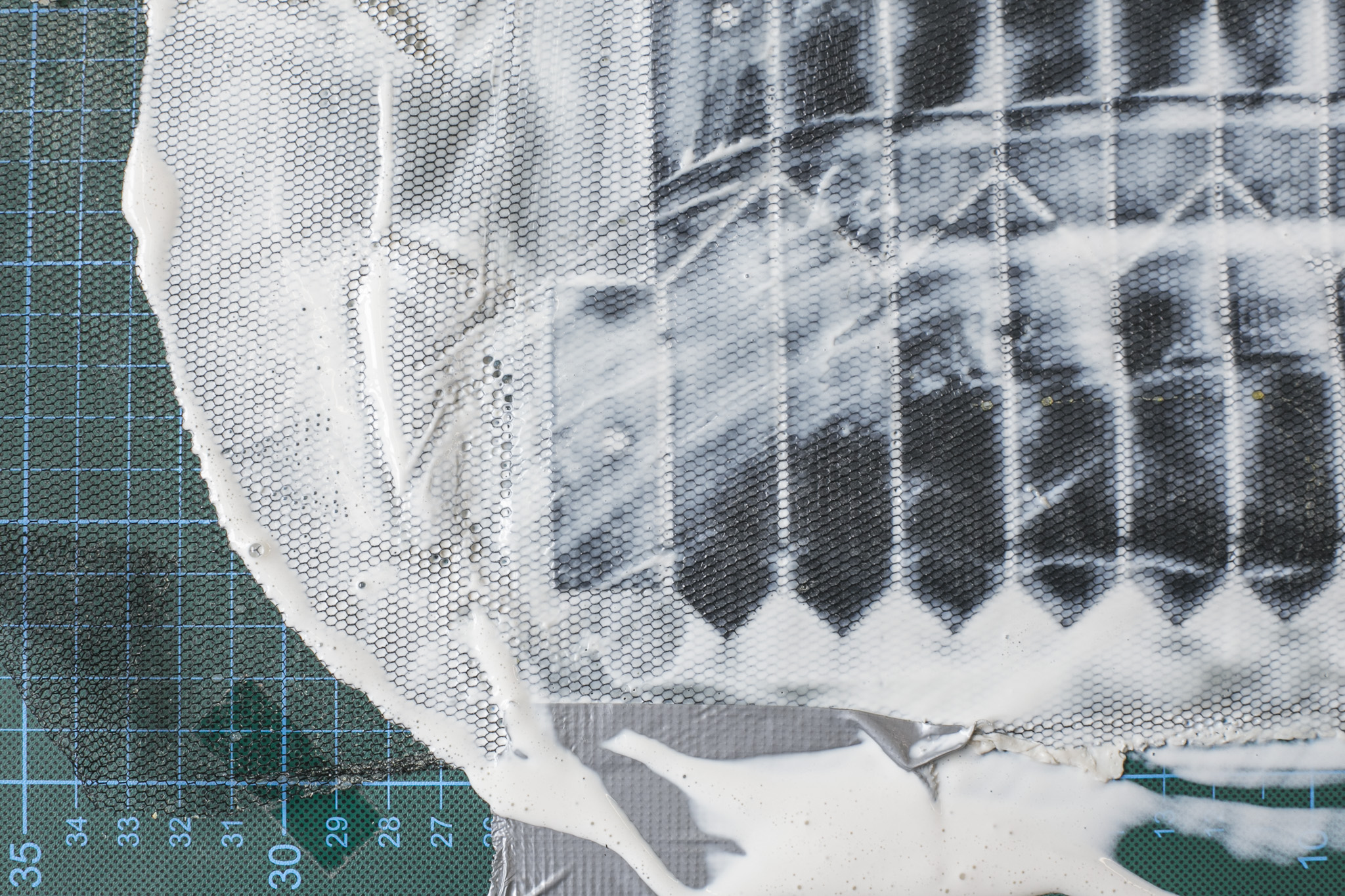

Coating preparation

You will need an assistant for the following steps.

Cut transfer adhesive film to about 50cm x 100cm and remove its protective sheet starting at one corner, pulling diagonally and almost parallel to the surface.

While one person positions the transparent film parallel to the end of the cut cardboard (mirrored side up!), the other holds up the other end.

The film should protrude the cardboard on every side.

cut transfer adhesive film to 50cm x 100cm

cut transfer adhesive film to 50cm x 100cm

removing film from paper, start at one corner and pull diagonal and parallel to surface

removing film from paper, start at one corner and pull diagonal and parallel to surface

While one person positions the transparent film parallel to the end of the cut cardboard (mirrored side up!), the other holds up the other end. The film should protrude the cardboard on every side.

While one person positions the transparent film parallel to the end of the cut cardboard (mirrored side up!), the other holds up the other end. The film should protrude the cardboard on every side.

Starting at one corner, wipe-press a cloth over the foil to stick it to the cardboard. While brushing from left to right, move slowly from one end of the cardboard to the other.

Starting at one corner, wipe-press a cloth over the foil to stick it to the cardboard. While brushing from left to right, move slowly from one end of the cardboard to the other.

transparent film properly mounted on sheet

transparent film properly mounted on sheet

cut mosquito netting to 50 x 100cm

cut mosquito netting to 50 x 100cm

apply adhesive spray to cardboard

apply adhesive spray to cardboard

apply adhesive spray to mosquito net

apply adhesive spray to mosquito net

Wait 10 minutes before mounting mosquito net on cardboard, adhesive spray needs to be dry

Mount mosquito net to the cardboard in the same way as you applied the transparent adhesive film before. Adjust its position by hand if necessary. Avoid wrinkles!

Mount mosquito net to the cardboard in the same way as you applied the transparent adhesive film before. Adjust its position by hand if necessary. Avoid wrinkles!

Use a rubber roll to evenly apply pressure. Not the time but the amount of pressure determines the quality of the connection.

Use a rubber roll to evenly apply pressure. Not the time but the amount of pressure determines the quality of the connection.

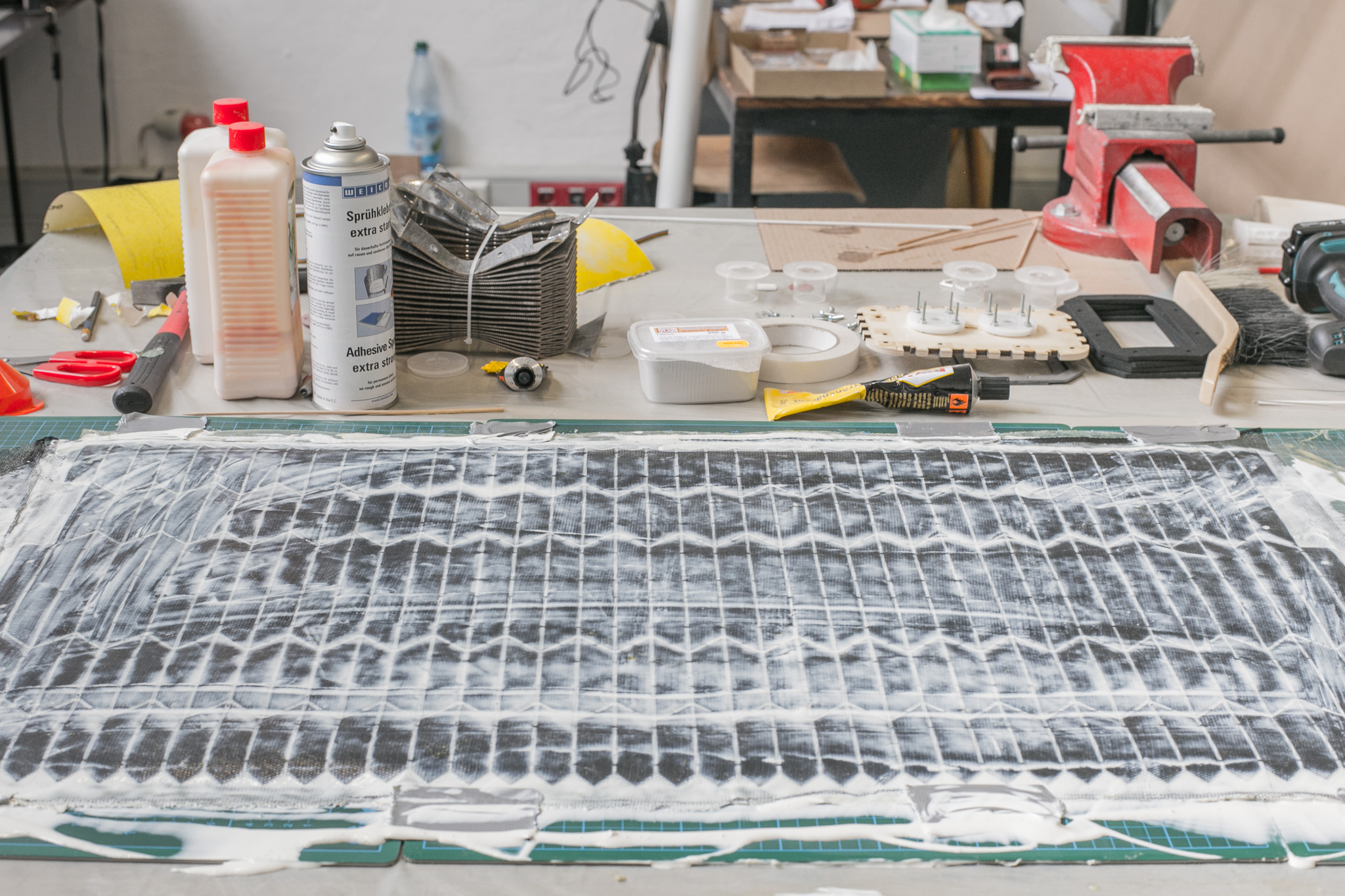

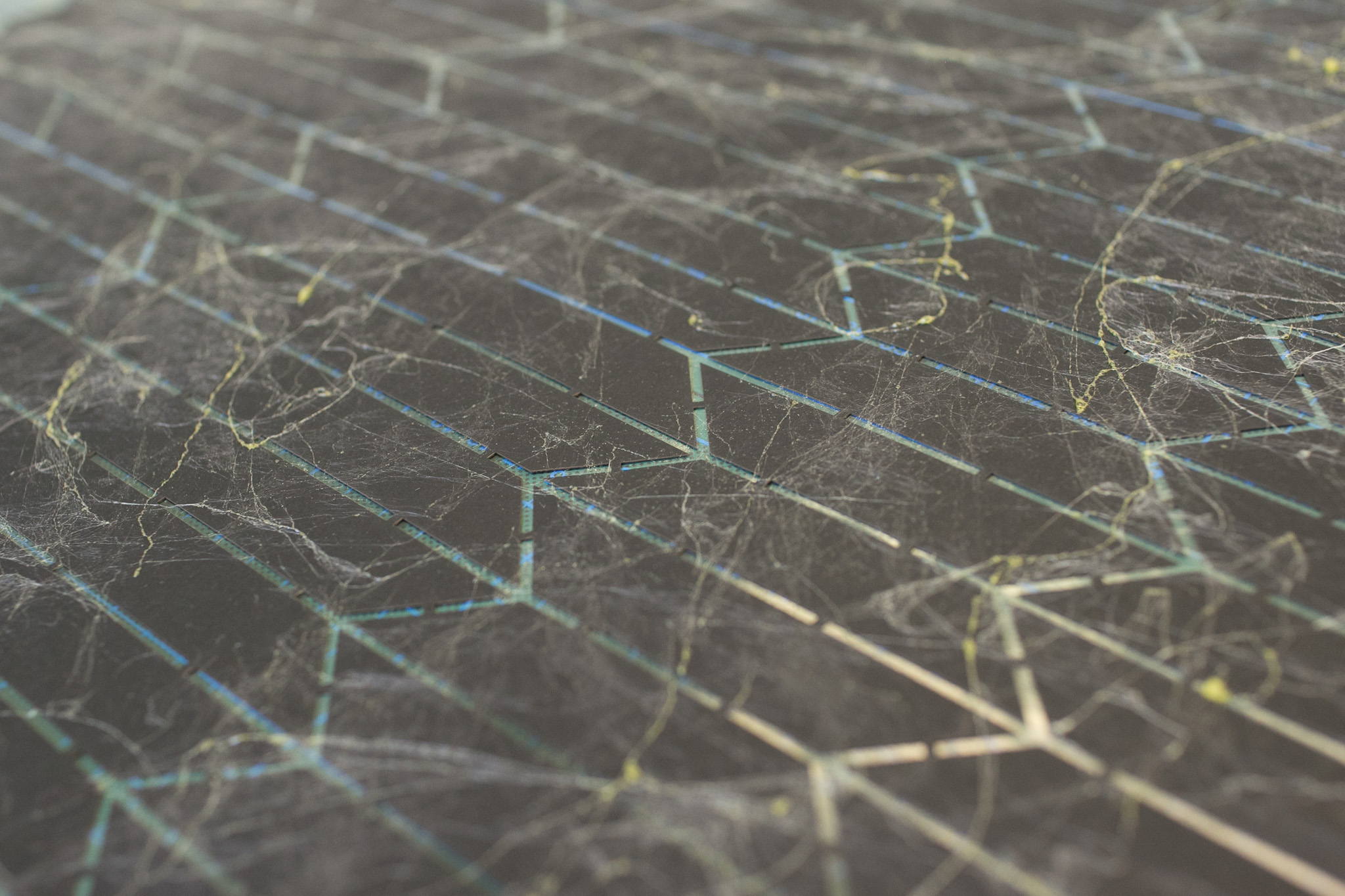

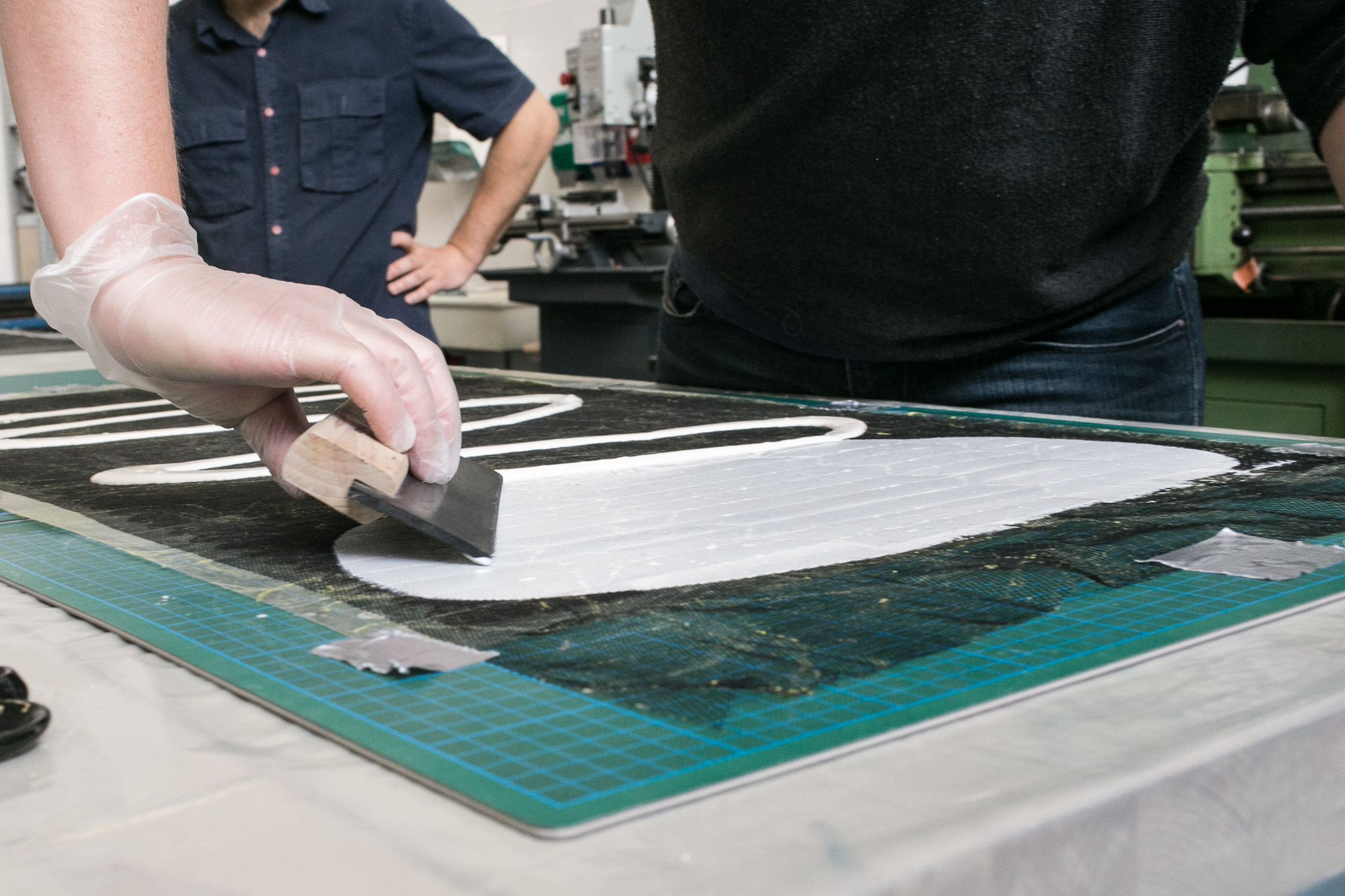

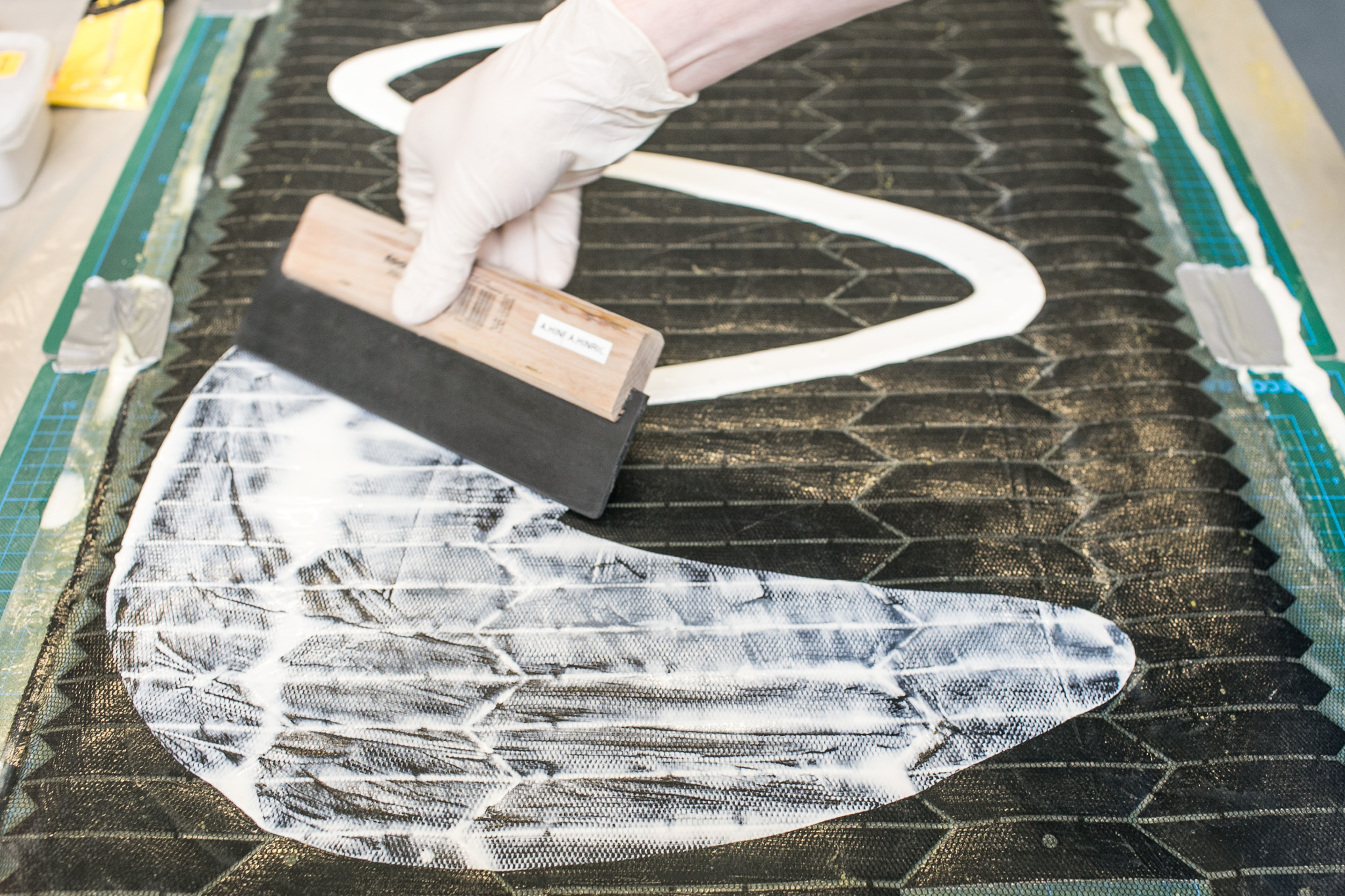

Coating

Put on vinyl gloves, and repeat coating three times. Thin layers of latex are better, wait for one layer to fully dry until you apply the next layer. This takes more or less 2 hours.

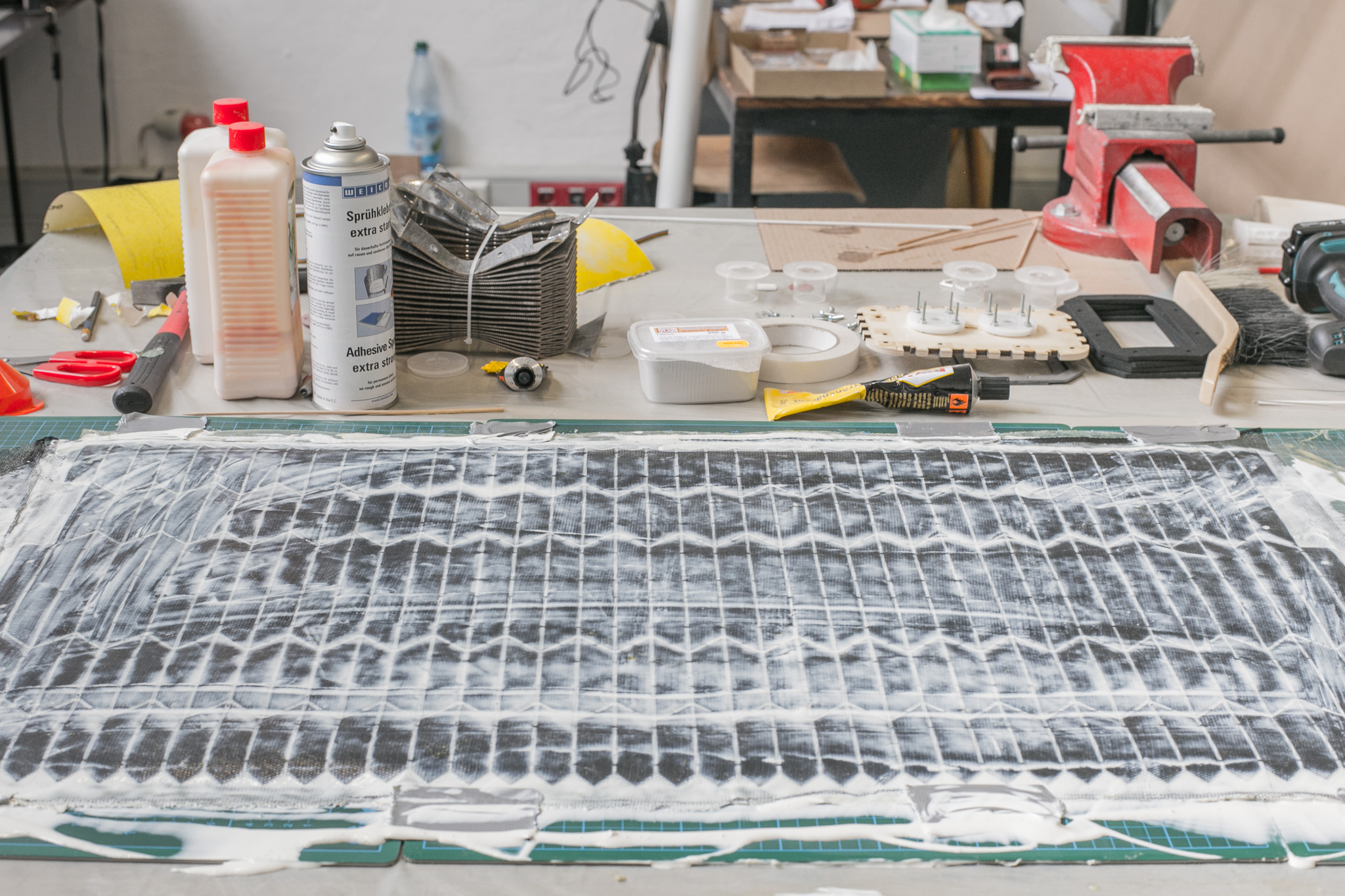

tape material to working surface, it should be strapped with a proper amount of tension

tape material to working surface, it should be strapped with a proper amount of tension

Pour more or less 300m of liquid latex on material

Pour more or less 300m of liquid latex on material

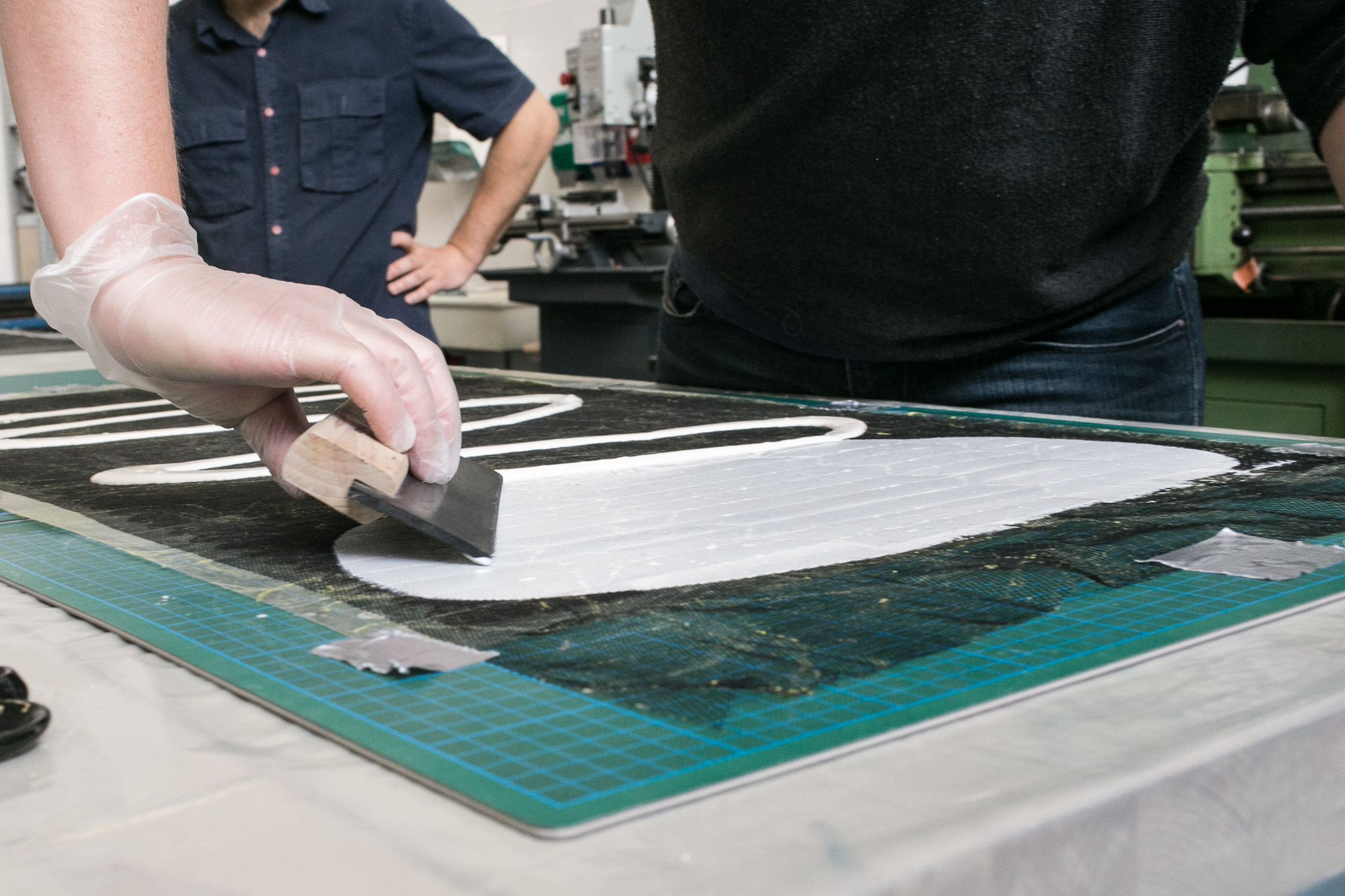

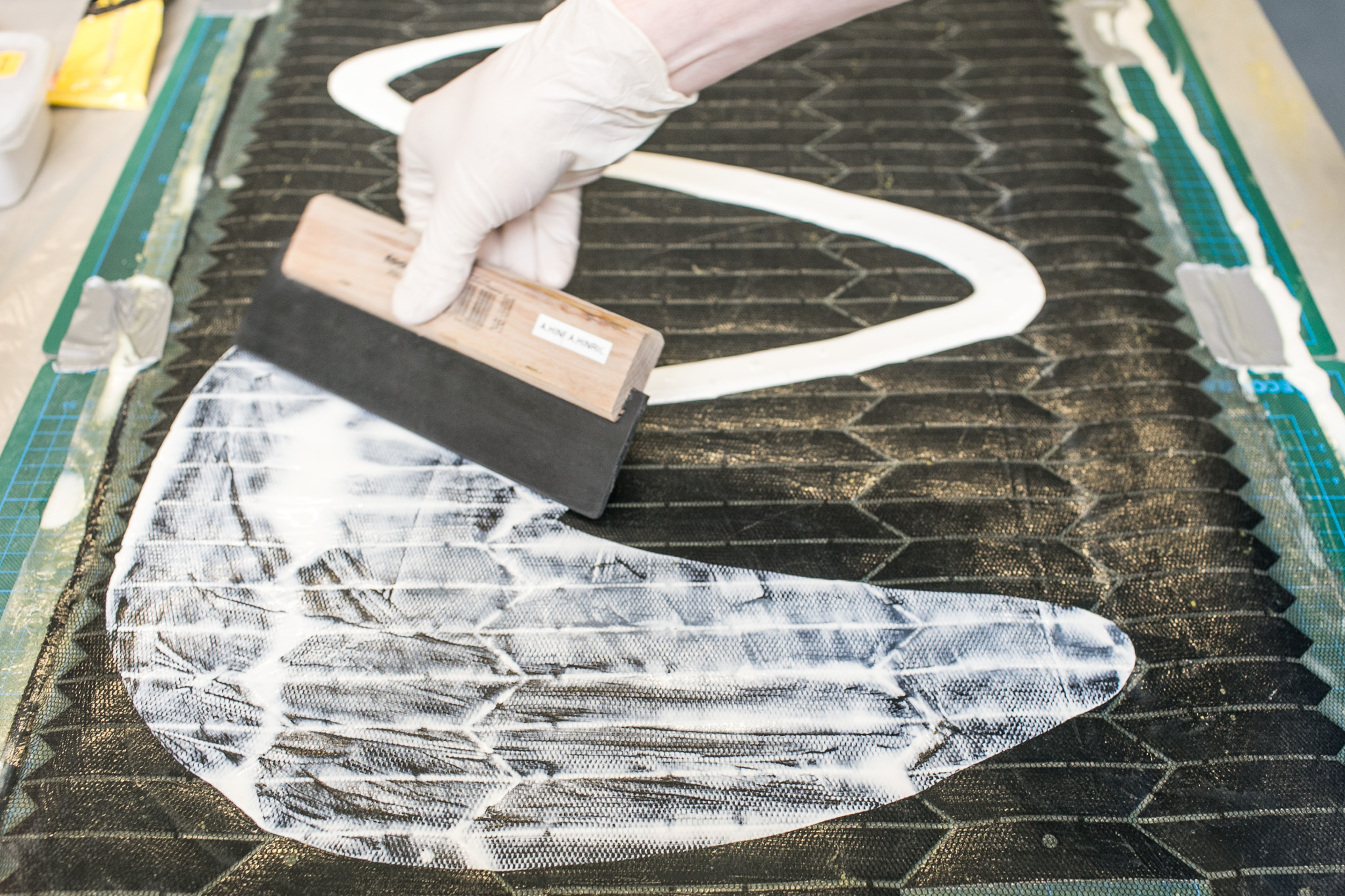

spread liquid latex on surface evenly

spread liquid latex on surface evenly

the more diagonal you hold the rubber spreader the easier you can spread the latex into the mosquito net

the more diagonal you hold the rubber spreader the easier you can spread the latex into the mosquito net

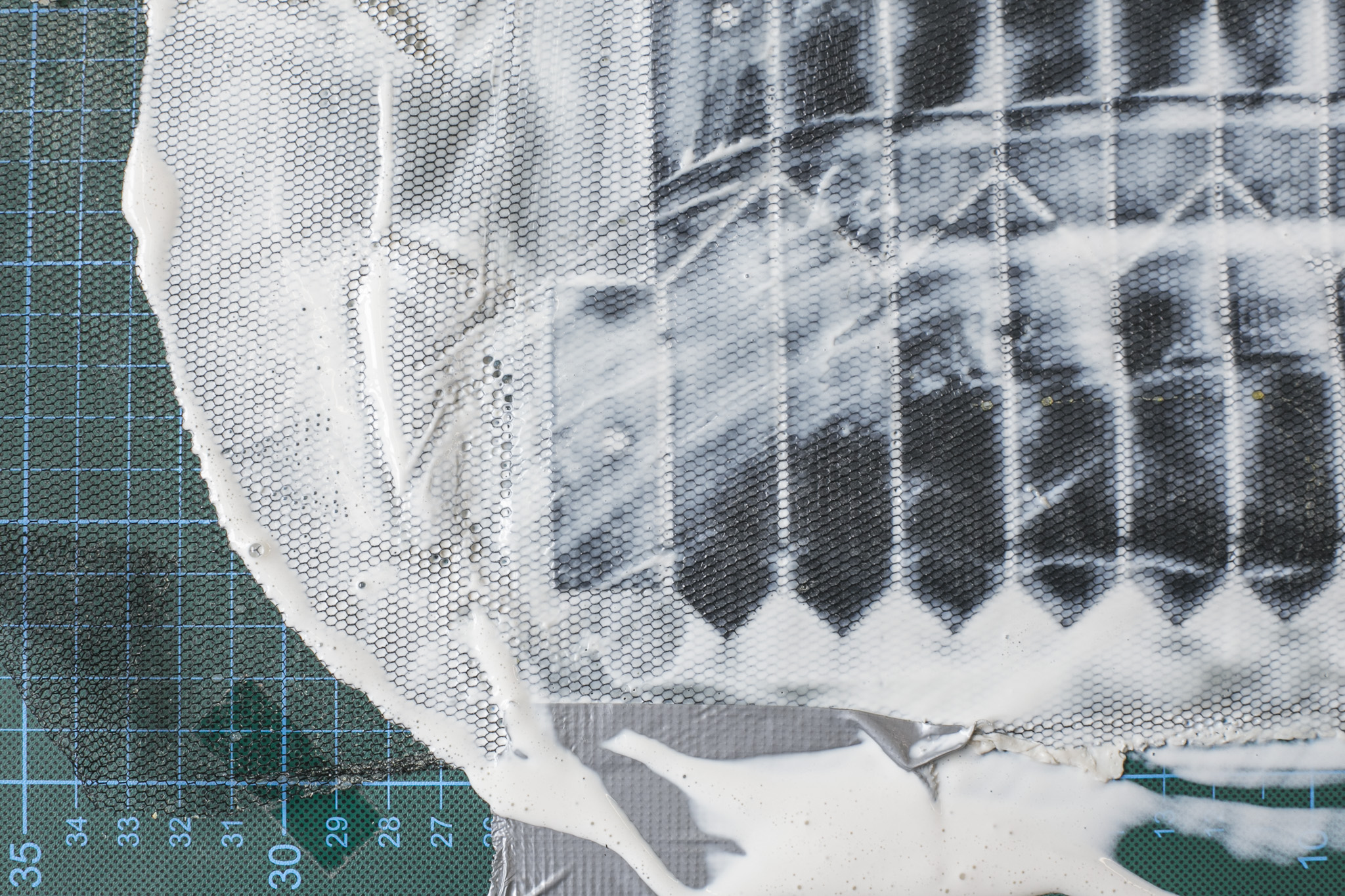

take care of the edges, they should be fully covered by latex.

take care of the edges, they should be fully covered by latex.

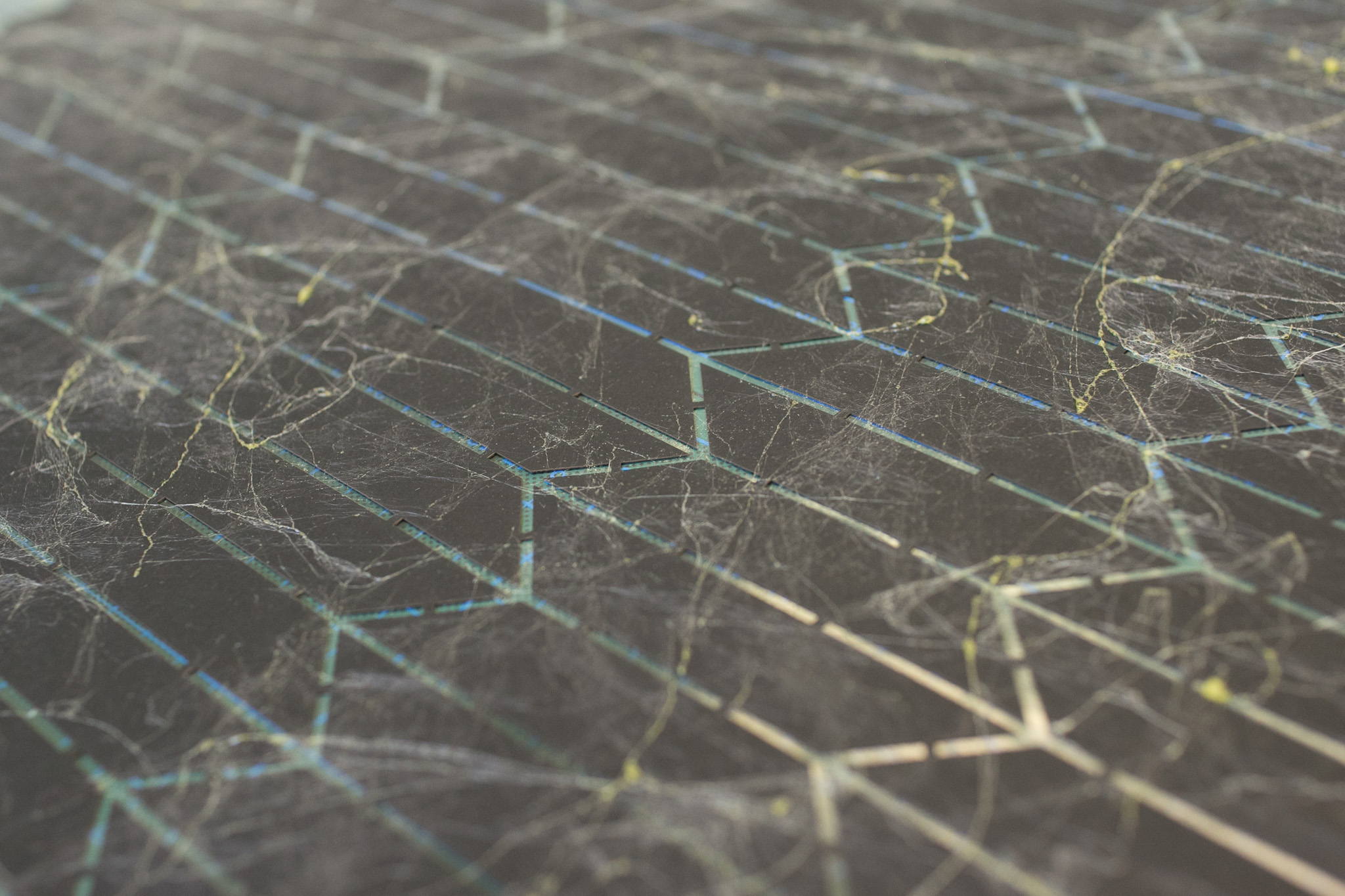

coated material, avoid dabs, if they happen spread them with your fingertip

coated material, avoid dabs, if they happen spread them with your fingertip

Preparing putting

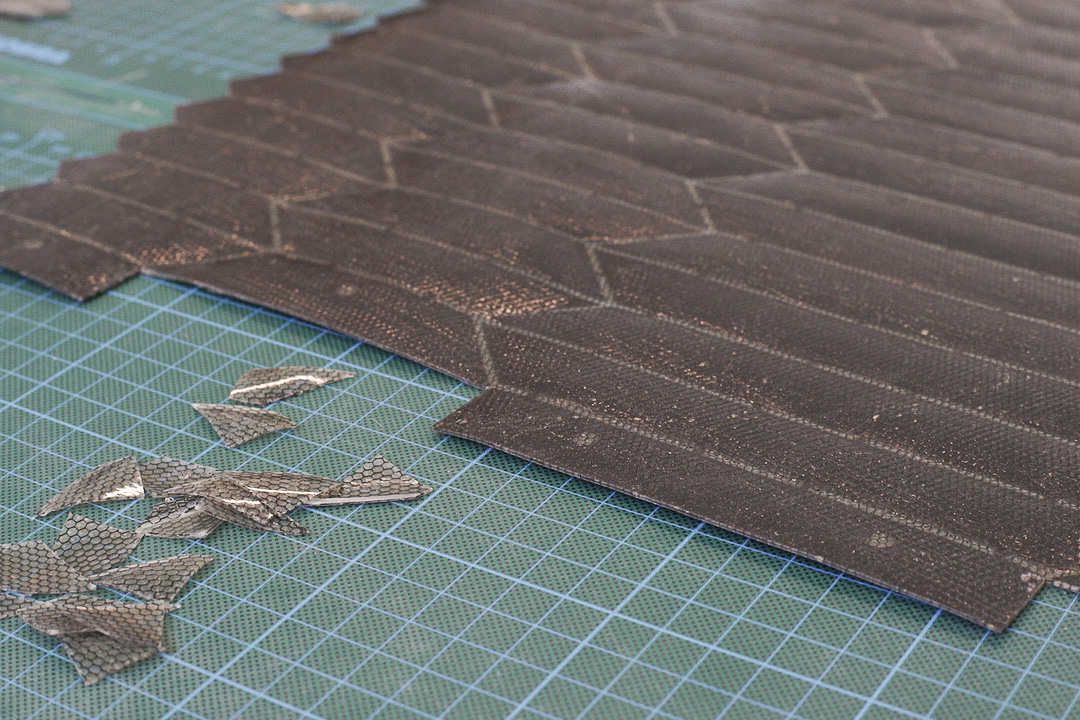

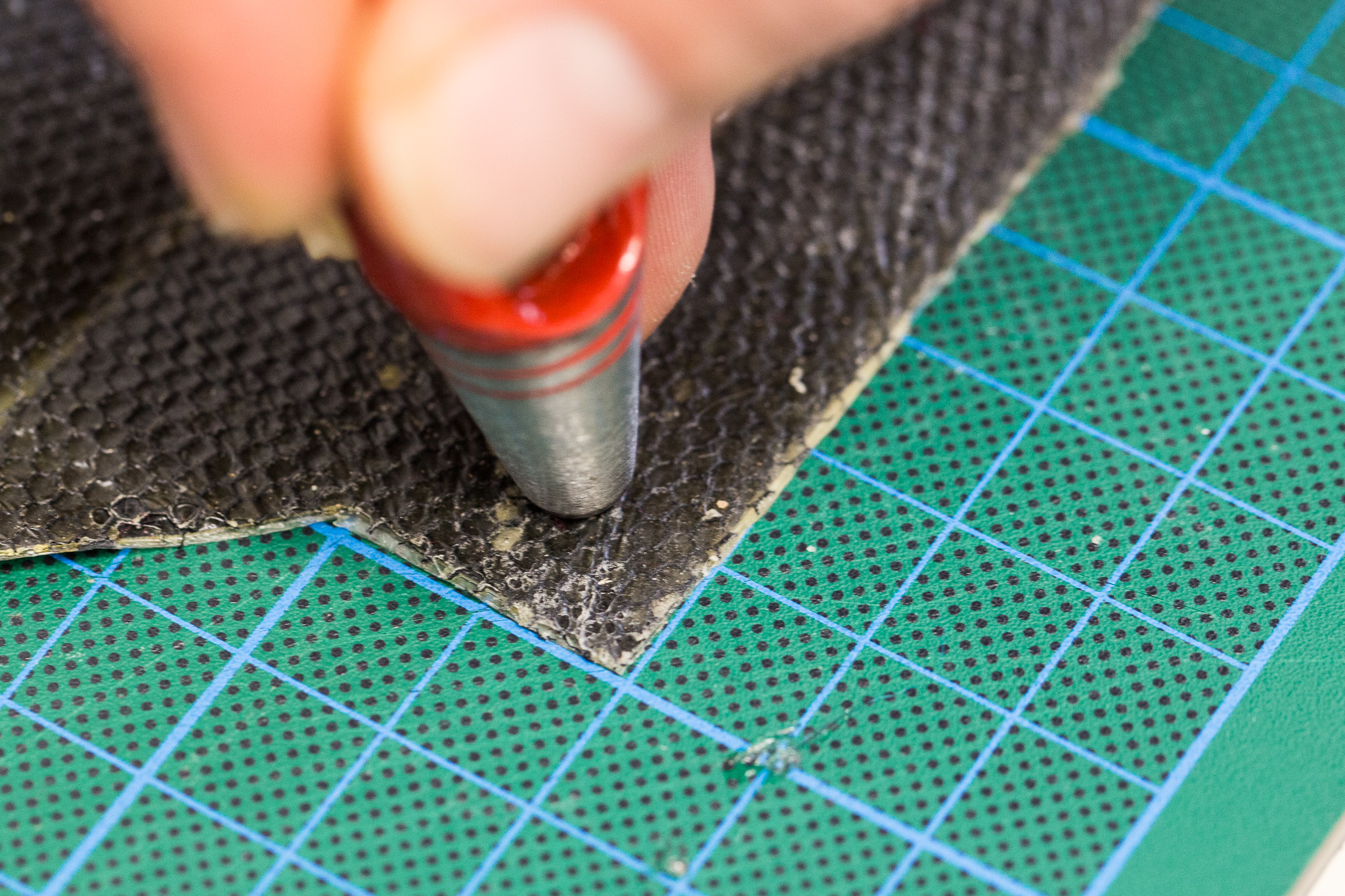

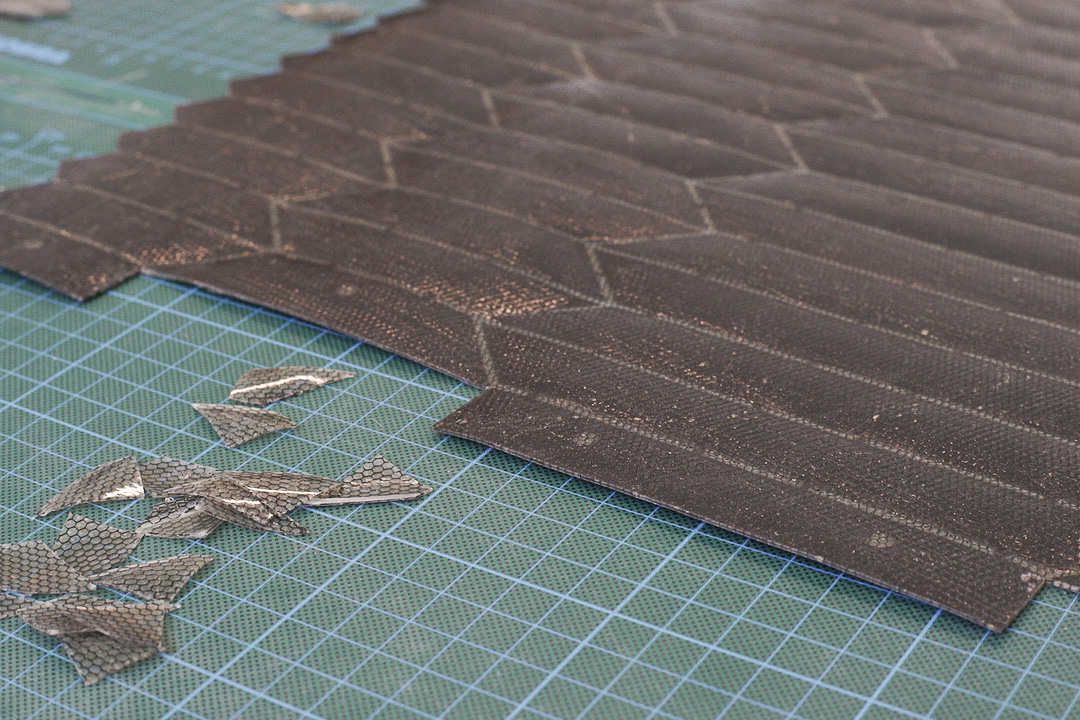

detach material from surface and cut along the edges

detach material from surface and cut along the edges

here as shown on the sides

here as shown on the sides

here as shown on the bottom part

here as shown on the bottom part

cut away excess material.

cut away excess material.

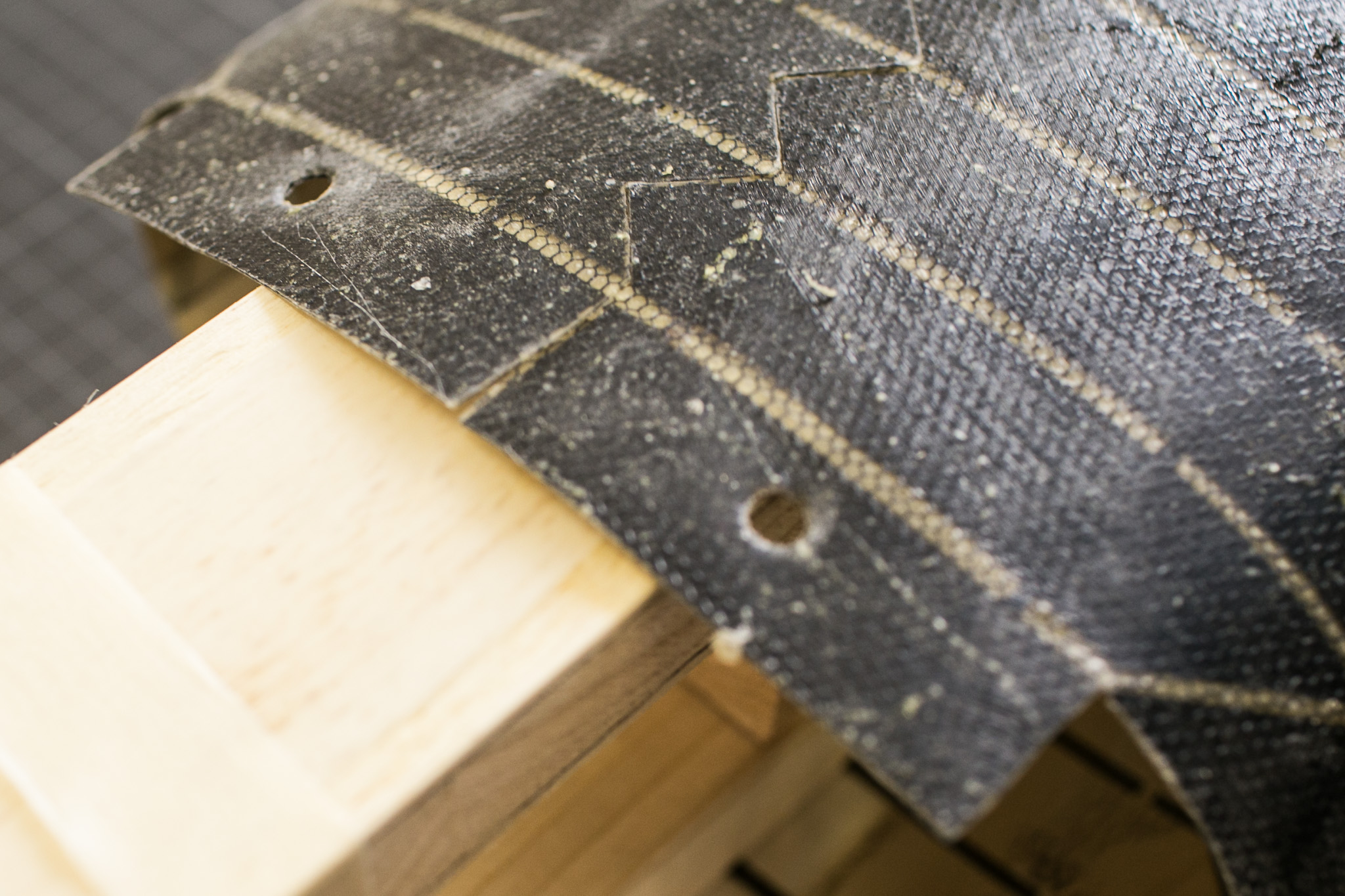

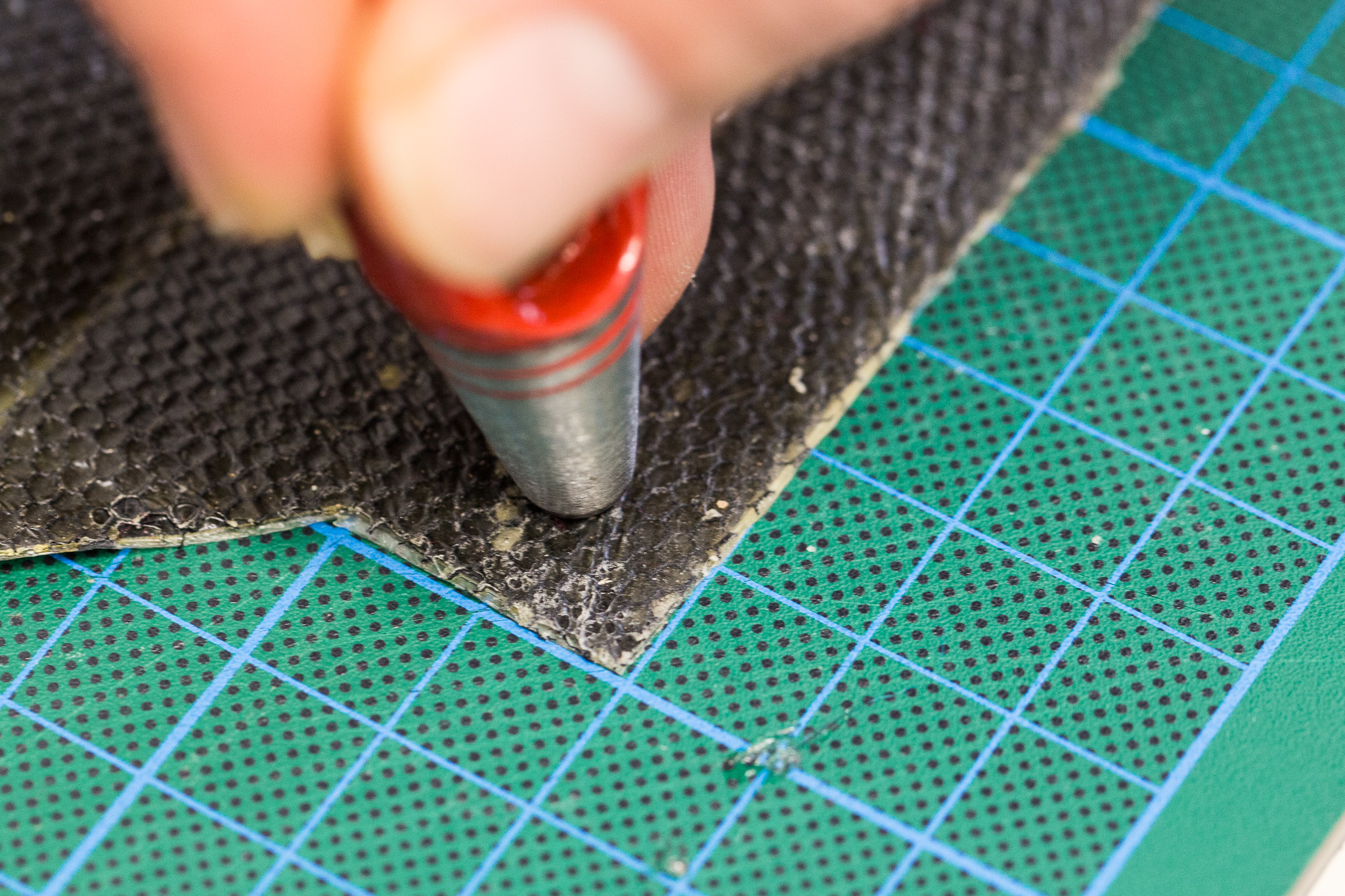

cut wholes with hollow puncher.

cut wholes with hollow puncher.

Remove adhesive transfer film from the mirror side of the material. it is very important to remove it by pulling slowly, parallel and close to the surface. that way you won’t rip latex out of the spacings in between the material

Remove adhesive transfer film from the mirror side of the material. it is very important to remove it by pulling slowly, parallel and close to the surface. that way you won’t rip latex out of the spacings in between the material

Putting

For the following steps it is much easier to work with somebody who can give you hand.

put a log of wood in the middle of coated sheet as supporting structure during the putting process

put a log of wood in the middle of coated sheet as supporting structure during the putting process

put the strip of adhesive film on the log (adhesive side up) and fix it with tape at each end of the log

put the strip of adhesive film on the log (adhesive side up) and fix it with tape at each end of the log

bend one half of the sheet towards the adhesive foil on the log so that it sticks there

bend one half of the sheet towards the adhesive foil on the log so that it sticks there

bend the other half

bend the other half

start at one end putting both ends together

start at one end putting both ends together

slowly moving up, triangles need to interlock

slowly moving up, triangles need to interlock

cut strip of latex textile 4cm x 95cm

cut strip of latex textile 4cm x 95cm

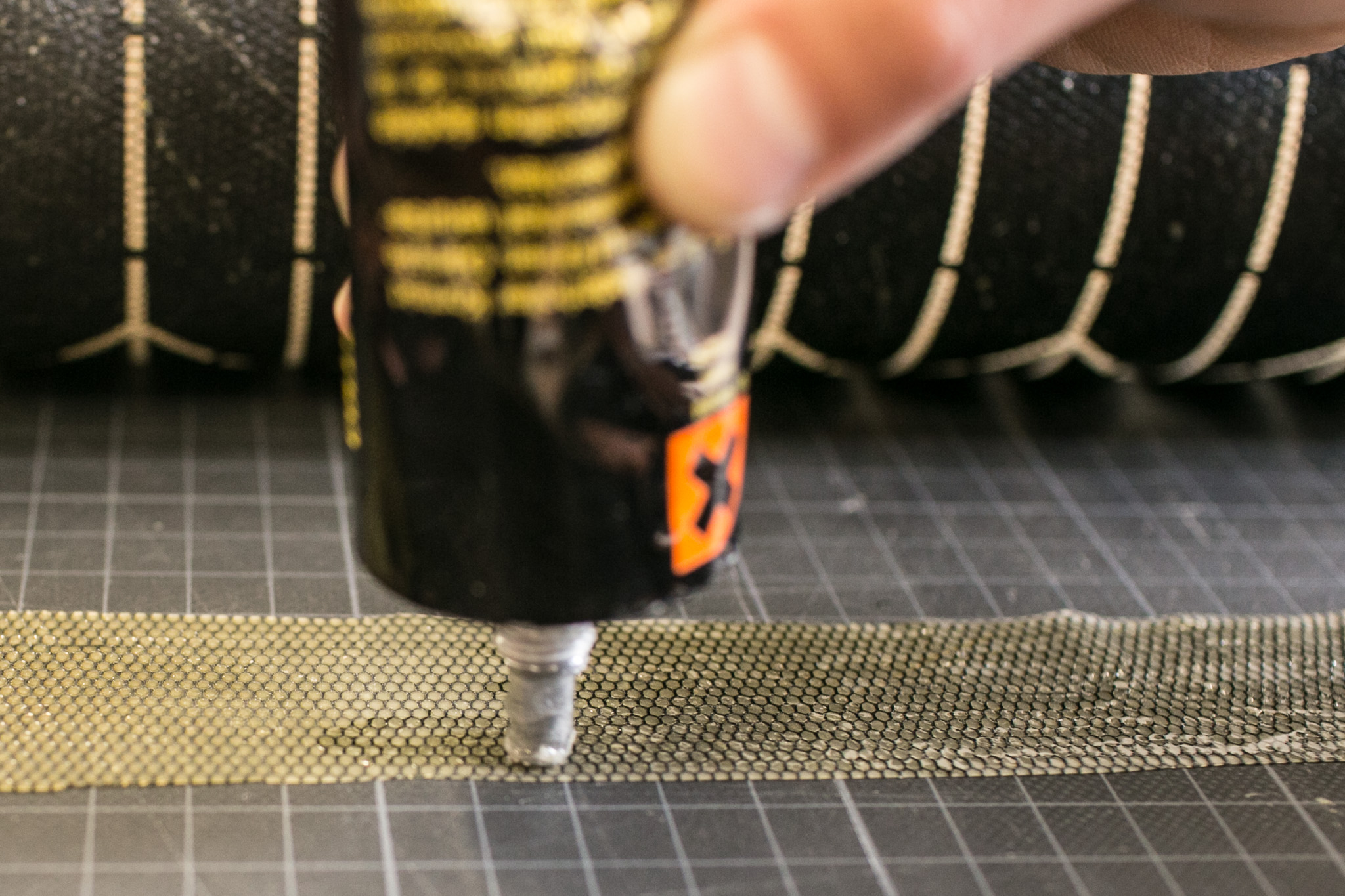

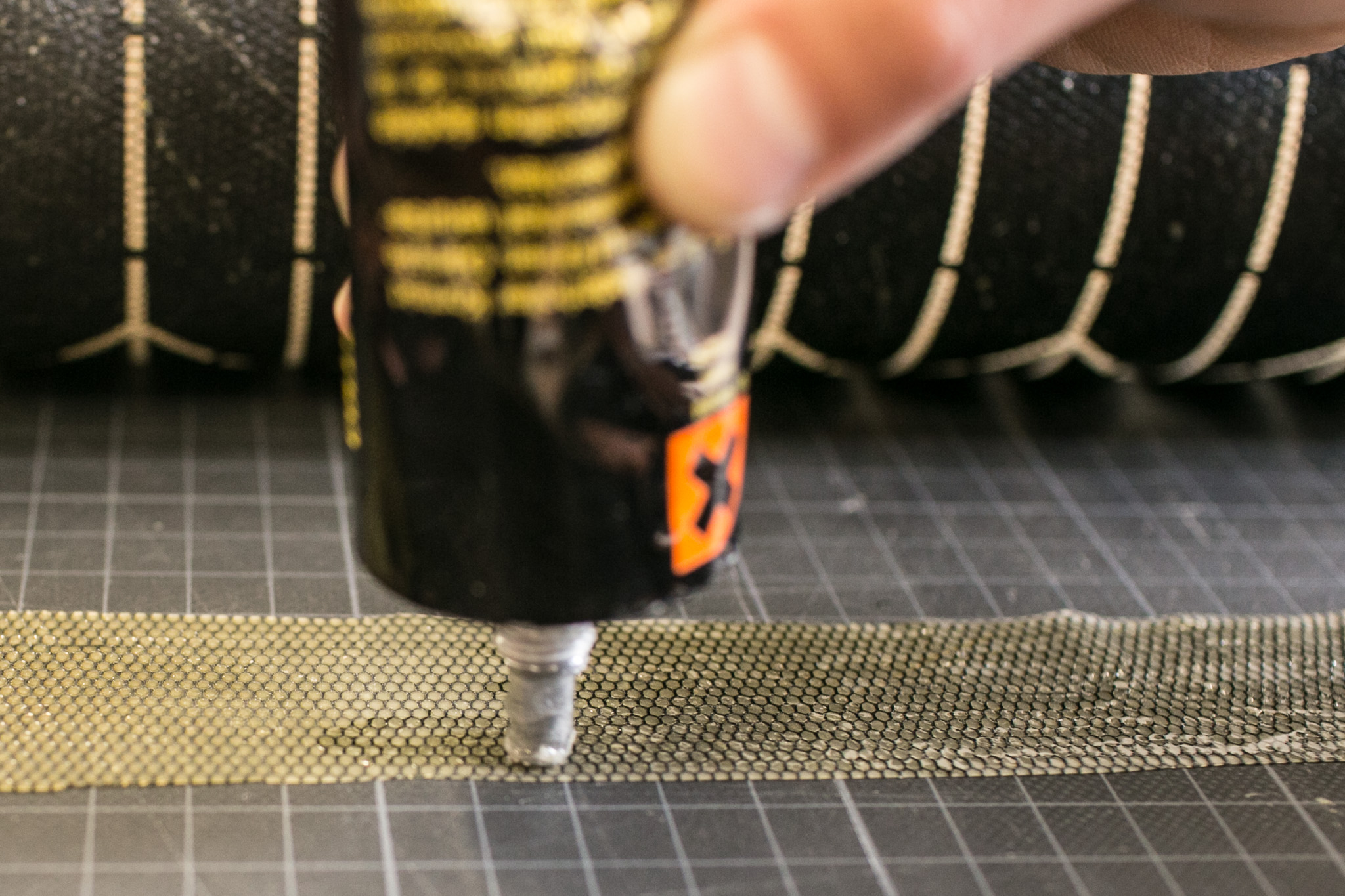

apply a 4 cm wide strip contact glue to the bellow’s seam.

apply a 4 cm wide strip contact glue to the bellow’s seam.

apply contact glue on latex textile strip

apply contact glue on latex textile strip

When the glue has fully dried glue strip to seam by applying pressure with rubber roll.

When the glue has fully dried glue strip to seam by applying pressure with rubber roll.

bellow with proper applied strip

bellow with proper applied strip

Apply latex with brush along the edges of the strip

Apply latex with brush along the edges of the strip

spreading latex with fingertips

spreading latex with fingertips

Folding

cut the edges of the short ribs at each side of the bellow

cut the edges of the short ribs at each side of the bellow

apply talcum evenly on surface

apply talcum evenly on surface

Fold bellow

Fold bellow

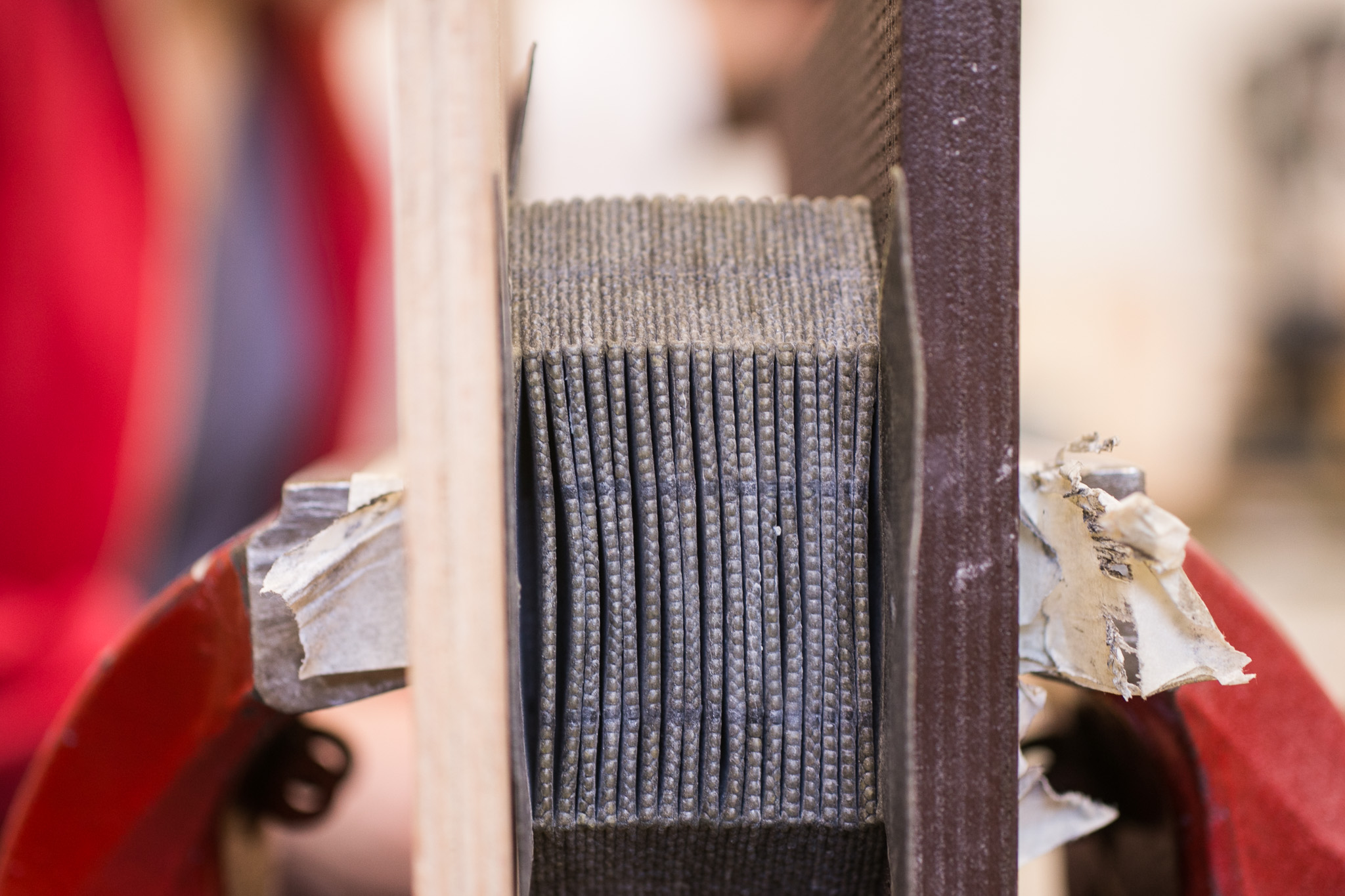

Completely folded bellow

Completely folded bellow

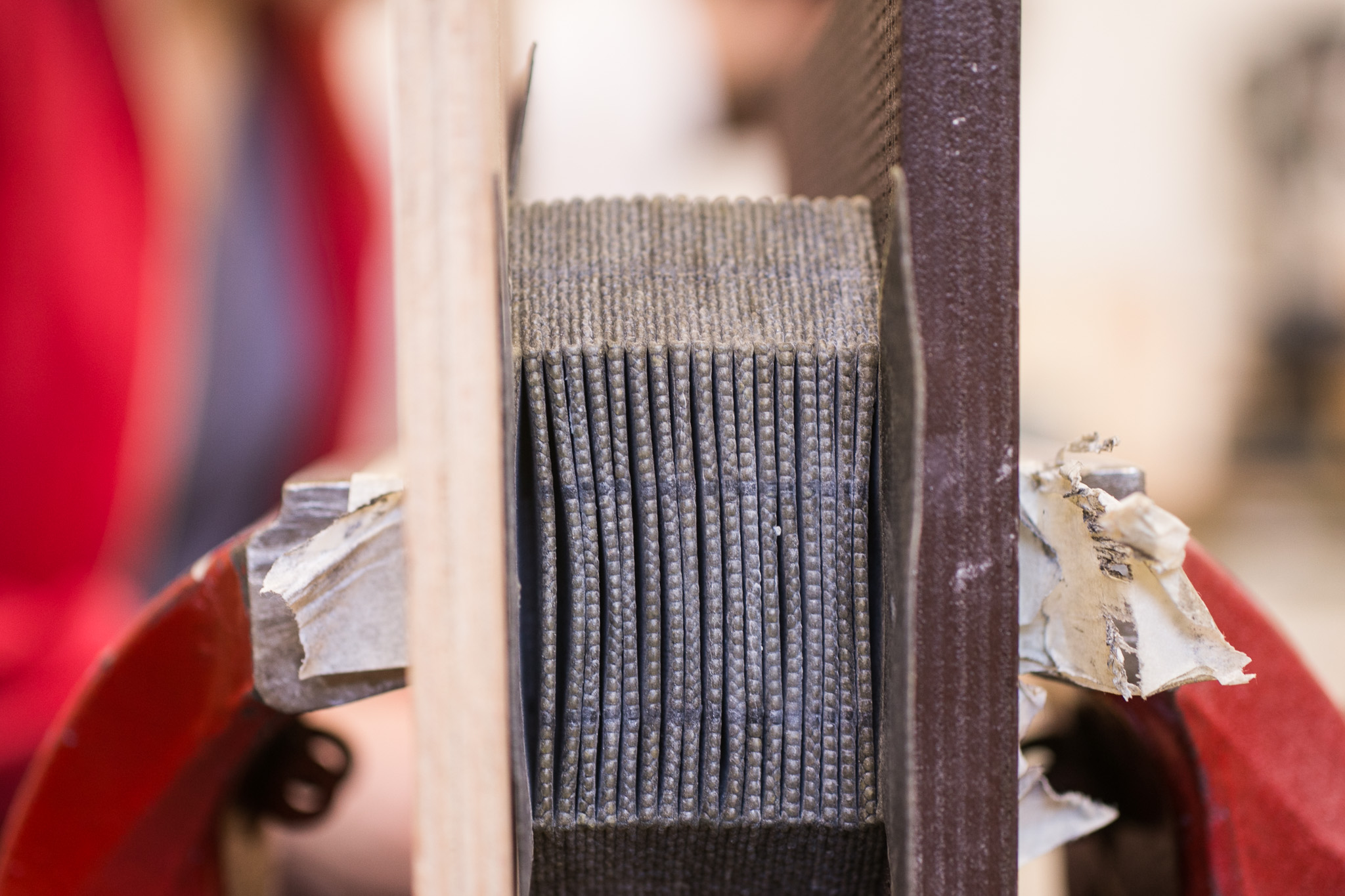

Clamp the bellow over night so it will stay in folded position. It it not necessary to apply a lot of pressure. Just that it is stable.

Clamp the bellow over night so it will stay in folded position. It it not necessary to apply a lot of pressure. Just that it is stable.

Glueing

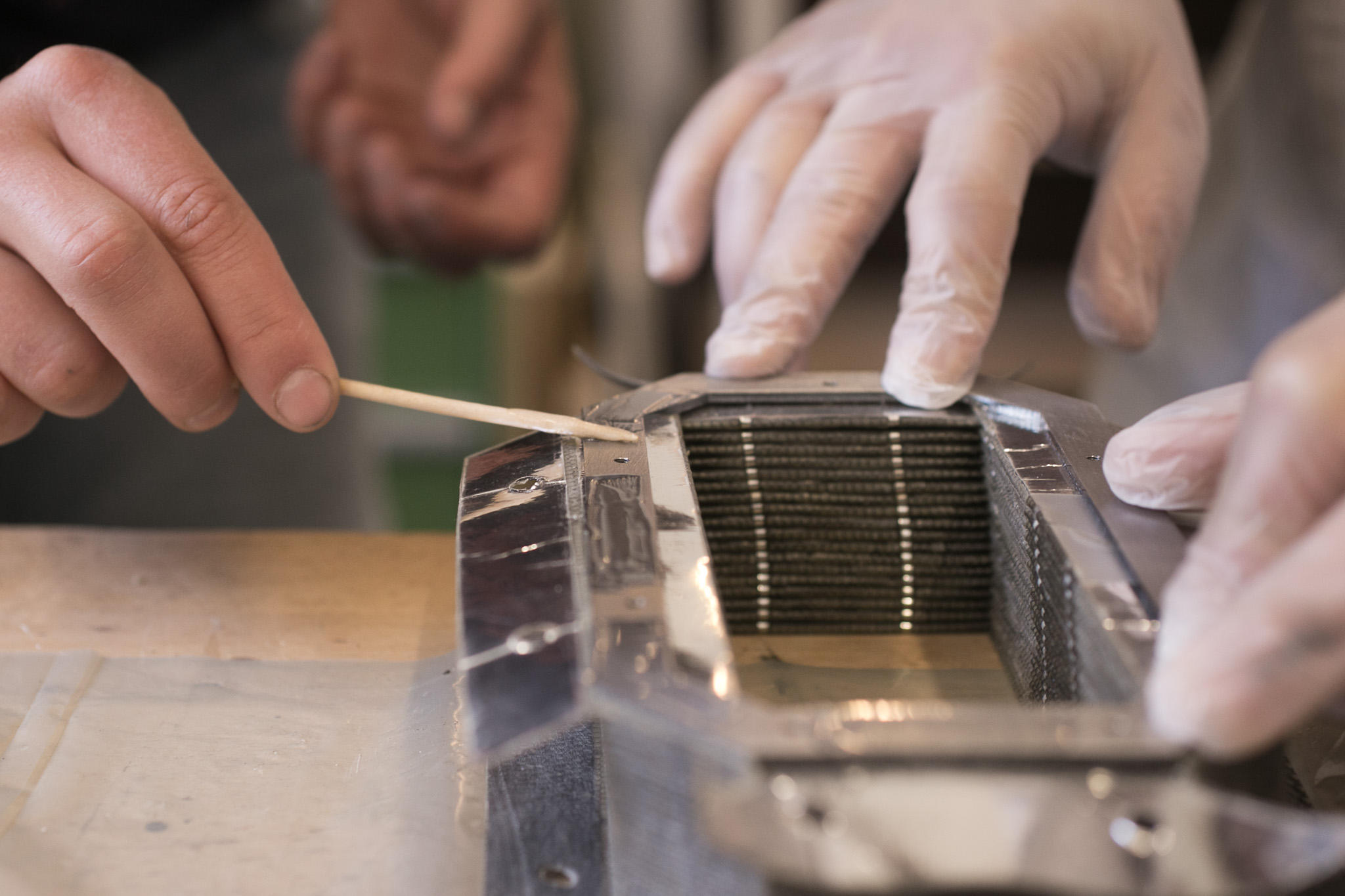

While glueing in the metal frames at each end of the bellow work with another person. before glueing make sure metal parts are fat and dust free. Glue one frame at a time since the epoxy hardens quiet fast!

Put metal frame inside the last fold of the bellow, make sure that the holes are in the same positions as in the bellow and apply a thin layer of epoxy in between the holes. Leave 1 cm space between holes and epoxy to make sure that no glue will go into the female screw thread.

Put metal frame inside the last fold of the bellow, make sure that the holes are in the same positions as in the bellow and apply a thin layer of epoxy in between the holes. Leave 1 cm space between holes and epoxy to make sure that no glue will go into the female screw thread.

Fold the end of the bellow around the metal.

Fold the end of the bellow around the metal.

take care that holes of metal frames and below are aligned.

take care that holes of metal frames and below are aligned.

Clamp bellow, not to apply a lot of pressure, rather to stabilise the last foldings of the bellow

Clamp bellow, not to apply a lot of pressure, rather to stabilise the last foldings of the bellow

let it sit until epoxy is hardened

let it sit until epoxy is hardened

apply latex on the naked metal edges at each end of the bellow

apply latex on the naked metal edges at each end of the bellow

done!

done!

tools and some of the materials

tools and some of the materials folded bellow with metal frames

folded bellow with metal frames cut transfer adhesive film to 50cm x 100cm

cut transfer adhesive film to 50cm x 100cm removing film from paper, start at one corner and pull diagonal and parallel to surface

removing film from paper, start at one corner and pull diagonal and parallel to surface While one person positions the transparent film parallel to the end of the cut cardboard (mirrored side up!), the other holds up the other end. The film should protrude the cardboard on every side.

While one person positions the transparent film parallel to the end of the cut cardboard (mirrored side up!), the other holds up the other end. The film should protrude the cardboard on every side. Starting at one corner, wipe-press a cloth over the foil to stick it to the cardboard. While brushing from left to right, move slowly from one end of the cardboard to the other.

Starting at one corner, wipe-press a cloth over the foil to stick it to the cardboard. While brushing from left to right, move slowly from one end of the cardboard to the other. transparent film properly mounted on sheet

transparent film properly mounted on sheet cut mosquito netting to 50 x 100cm

cut mosquito netting to 50 x 100cm apply adhesive spray to cardboard

apply adhesive spray to cardboard apply adhesive spray to mosquito net

apply adhesive spray to mosquito net Mount mosquito net to the cardboard in the same way as you applied the transparent adhesive film before. Adjust its position by hand if necessary. Avoid wrinkles!

Mount mosquito net to the cardboard in the same way as you applied the transparent adhesive film before. Adjust its position by hand if necessary. Avoid wrinkles! Use a rubber roll to evenly apply pressure. Not the time but the amount of pressure determines the quality of the connection.

Use a rubber roll to evenly apply pressure. Not the time but the amount of pressure determines the quality of the connection. tape material to working surface, it should be strapped with a proper amount of tension

tape material to working surface, it should be strapped with a proper amount of tension Pour more or less 300m of liquid latex on material

Pour more or less 300m of liquid latex on material spread liquid latex on surface evenly

spread liquid latex on surface evenly the more diagonal you hold the rubber spreader the easier you can spread the latex into the mosquito net

the more diagonal you hold the rubber spreader the easier you can spread the latex into the mosquito net take care of the edges, they should be fully covered by latex.

take care of the edges, they should be fully covered by latex. coated material, avoid dabs, if they happen spread them with your fingertip

coated material, avoid dabs, if they happen spread them with your fingertip detach material from surface and cut along the edges

detach material from surface and cut along the edges here as shown on the sides

here as shown on the sides here as shown on the bottom part

here as shown on the bottom part cut away excess material.

cut away excess material. cut wholes with hollow puncher.

cut wholes with hollow puncher. Remove adhesive transfer film from the mirror side of the material. it is very important to remove it by pulling slowly, parallel and close to the surface. that way you won’t rip latex out of the spacings in between the material

Remove adhesive transfer film from the mirror side of the material. it is very important to remove it by pulling slowly, parallel and close to the surface. that way you won’t rip latex out of the spacings in between the material put a log of wood in the middle of coated sheet as supporting structure during the putting process

put a log of wood in the middle of coated sheet as supporting structure during the putting process put the strip of adhesive film on the log (adhesive side up) and fix it with tape at each end of the log

put the strip of adhesive film on the log (adhesive side up) and fix it with tape at each end of the log bend one half of the sheet towards the adhesive foil on the log so that it sticks there

bend one half of the sheet towards the adhesive foil on the log so that it sticks there bend the other half

bend the other half start at one end putting both ends together

start at one end putting both ends together slowly moving up, triangles need to interlock

slowly moving up, triangles need to interlock cut strip of latex textile 4cm x 95cm

cut strip of latex textile 4cm x 95cm apply a 4 cm wide strip contact glue to the bellow’s seam.

apply a 4 cm wide strip contact glue to the bellow’s seam. apply contact glue on latex textile strip

apply contact glue on latex textile strip When the glue has fully dried glue strip to seam by applying pressure with rubber roll.

When the glue has fully dried glue strip to seam by applying pressure with rubber roll. bellow with proper applied strip

bellow with proper applied strip Apply latex with brush along the edges of the strip

Apply latex with brush along the edges of the strip spreading latex with fingertips

spreading latex with fingertips cut the edges of the short ribs at each side of the bellow

cut the edges of the short ribs at each side of the bellow apply talcum evenly on surface

apply talcum evenly on surface

Fold bellow

Fold bellow Completely folded bellow

Completely folded bellow Clamp the bellow over night so it will stay in folded position. It it not necessary to apply a lot of pressure. Just that it is stable.

Clamp the bellow over night so it will stay in folded position. It it not necessary to apply a lot of pressure. Just that it is stable. Put metal frame inside the last fold of the bellow, make sure that the holes are in the same positions as in the bellow and apply a thin layer of epoxy in between the holes. Leave 1 cm space between holes and epoxy to make sure that no glue will go into the female screw thread.

Put metal frame inside the last fold of the bellow, make sure that the holes are in the same positions as in the bellow and apply a thin layer of epoxy in between the holes. Leave 1 cm space between holes and epoxy to make sure that no glue will go into the female screw thread. Fold the end of the bellow around the metal.

Fold the end of the bellow around the metal. take care that holes of metal frames and below are aligned.

take care that holes of metal frames and below are aligned. Clamp bellow, not to apply a lot of pressure, rather to stabilise the last foldings of the bellow

Clamp bellow, not to apply a lot of pressure, rather to stabilise the last foldings of the bellow let it sit until epoxy is hardened

let it sit until epoxy is hardened apply latex on the naked metal edges at each end of the bellow

apply latex on the naked metal edges at each end of the bellow done!

done!